Grain Drying Process

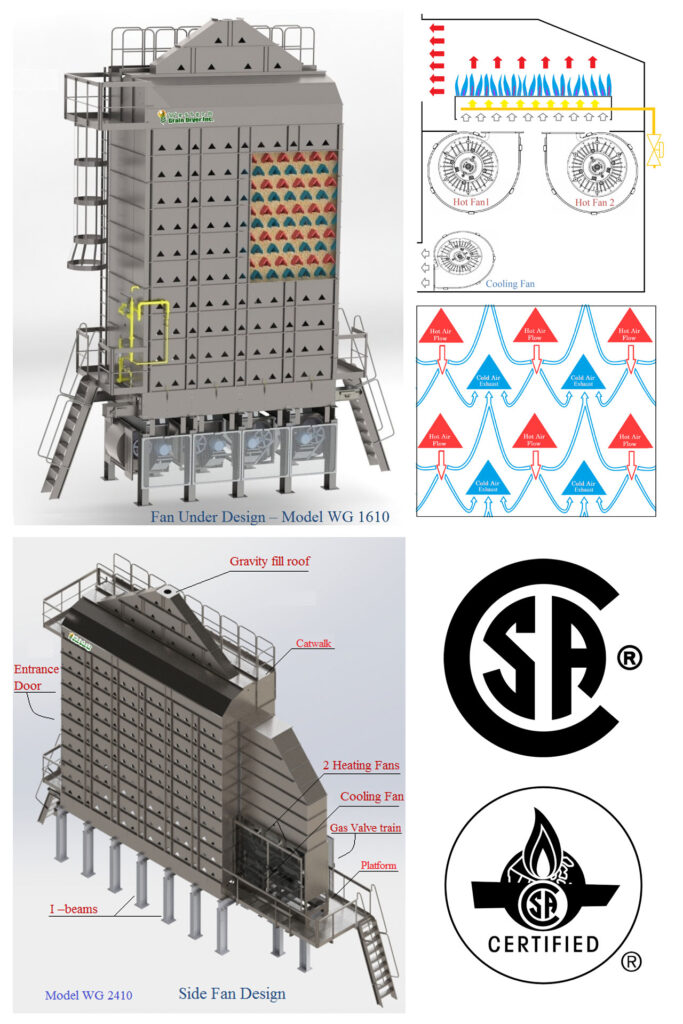

The standard design of Western Grain dryers consists of a full-cover roof and catwalk, drying section, cooling section, fans, burner, loading control systems and temperature control system. The dryer is top-loading with the drying being done in the upper section of the unit. In the lower section, cool air brings grain down approximately 20 Degree Fahrenheit above the outside air temperature before grain leaves the dryer; loading and unloading are automated. The controls of the dryer consist of controlling the speed of the unloading augers and the temperature of the drying air. The basic control function is to minimize over drying or under drying of the grain moisture content while maximizing dryer capacity under acceptable conditions of grain quality and energy consumption.

Western Grain dryers are mixed flow grain dryers. On a mixed flow dryer, the warm air enters the grain column through a series of warm air ducts. As result, the entire column from inside to the outside gets exposed to the warm air at the same time. In the meantime, grain is able to flow around the ducts on its way through the dryer, resulting in mixing action and the chance for the grain to get away from the warm air stream from time to time. This also allows the kernel to get a chance to move moisture from the center of the seed to the outside, resulting in a much more gentle drying process.

The practical result of this is that a mixed flow dryer can be used at higher plenum temperatures without incurring the kind of damage that would result in a cross flow dryer such as most of screen grain dryers or bin dryers. Moisture is extracted as seeds/grain float through uniform temperature fields with no screens or other obstructions. Our drying technology can prevent loss from inability to germinate and inclement weather.

Therefore, mixed-air flow design allows hot air to be evenly distributed throughout the grain columns, thereby avoid under or over drying